radial fan vs axial fan: A Comprehensive Comparison

When it comes to industrial ventilation and air movement systems, two popular options are radial fans and axial fans. While both are commonly used in various applications, they differ in design, performance, and suitability for specific tasks. In this article, we will delve into the differences between radial fans and axial fans, exploring their unique characteristics, advantages, and disadvantages. By the end, you will have a clear understanding of which type of fan is best suited for your specific needs.

1. Radial Fans: Introduction and Functionality

Radial fans, also known as centrifugal fans, are designed to move air or gas perpendicular to the fan's axis of rotation. These fans use centrifugal force to propel the air outward, creating pressure and increasing airflow. They are commonly used in applications that require high-pressure air movement, such as HVAC systems, industrial ventilation, and dust collection systems.

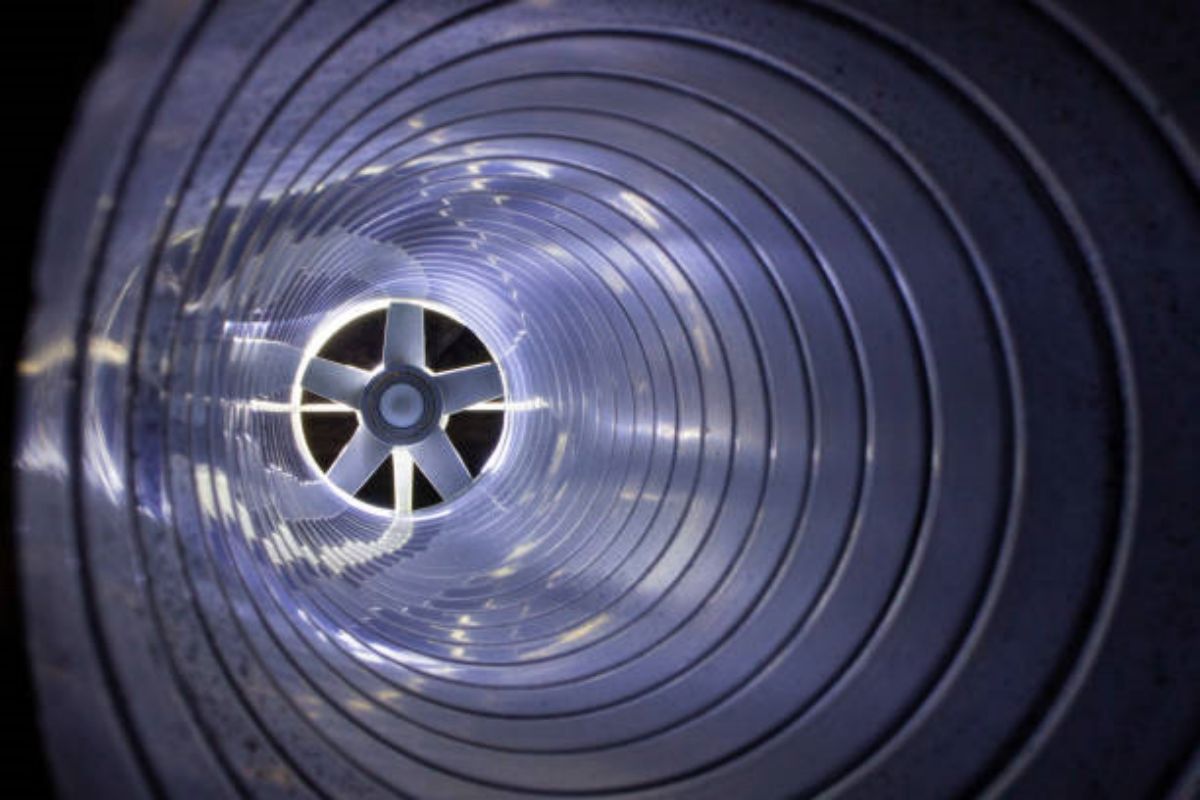

2. Axial Fans: Introduction and Functionality

Axial fans, on the other hand, are designed to move air or gas parallel to the fan's axis of rotation. These fans use a propeller-like blade design to generate airflow, pushing the air in a straight line. Axial fans are commonly used in applications where high airflow rates are required, such as cooling electronic equipment, exhaust systems, and air conditioning units.

3. Design and Construction

The design and construction of radial fans and axial fans are significantly different. Radial fans consist of a housing or casing with an impeller inside. The impeller contains blades that are curved or forward-curved, backward-curved, or straight radial. The air enters the fan housing axially and is then pushed out radially.

On the other hand, axial fans consist of a motor, propeller, and a cylindrical housing. The propeller blades are typically straight and mounted on a hub, which is connected to the motor. The air enters the fan axially and is pushed out in the same direction as the axis of rotation.

4. Airflow Characteristics

The airflow characteristics of radial fans and axial fans vary significantly. Radial fans are capable of generating higher pressures and are well-suited for applications that require high static pressure, such as ventilation systems with long ducts or systems that require air to pass through obstacles like filters or coils. The airflow in radial fans is more focused and directed.

On the other hand, axial fans are designed to move large volumes of air with lower pressure. They are more efficient in applications where the pressure drop is minimal, such as in open spaces or systems that do not involve obstacles. The airflow in axial fans is more diffuse and spread out.

5. Efficiency and Power Consumption

When it comes to efficiency and power consumption, axial fans have an advantage over radial fans. Axial fans are generally more efficient, as they require less energy to move large volumes of air. They are suitable for applications that prioritize high airflow rates and energy savings. Radial fans, on the other hand, require more power to generate higher pressures and are less efficient in terms of power consumption.

6. Noise Level

In terms of noise level, axial fans are typically quieter than radial fans. The design of axial fans allows for smoother airflow, resulting in reduced noise production. Radial fans, on the other hand, generate more noise due to the higher pressure and turbulence created during operation. If noise level is a critical factor in your application, an axial fan may be the better choice.

7. Space Requirements

When it comes to space requirements, axial fans are generally more compact and require less installation space compared to radial fans. This makes axial fans ideal for applications where space is limited or when a compact design is preferred. Radial fans, on the other hand, are bulkier and may require additional space for installation.

8. Maintenance and Serviceability

In terms of maintenance and serviceability, axial fans are generally easier to maintain. The simple design of axial fans with fewer components makes them easier to clean, inspect, and replace. Radial fans, on the other hand, have more complex designs and additional components, making maintenance and service more time-consuming and challenging.

9. Cost Considerations

When it comes to cost considerations, axial fans are generally more cost-effective compared to radial fans. Axial fans have simpler designs and fewer components, resulting in lower manufacturing and maintenance costs. Radial fans, with their more complex designs and additional components, are typically more expensive to manufacture and maintain.

10. Application Suitability

Finally, the choice between radial fans and axial fans ultimately depends on the specific application requirements. Radial fans are well-suited for applications that require high static pressure, such as ventilation systems with long ducts or systems with obstacles. Axial fans are ideal for applications that prioritize high airflow rates, energy savings, and compact design.

Conclusion

In conclusion, both radial fans and axial fans have their own unique characteristics, advantages, and disadvantages. Understanding these differences is essential in selecting the right fan for your specific application. Consider factors such as airflow requirements, pressure needs, space limitations, noise concerns, and maintenance considerations when choosing between a radial fan or an axial fan. By making an informed decision, you can ensure optimal performance and efficiency for your ventilation and air movement needs.